The past month or so has been primarily occupied by work on electrical wiring and construction of the stairs. (Ok, there was that ONE trip to Kauai, but other than that, we’ve been hard at work inside the house.)

The stairs are built from 4”x 15” natural edge “stringers” (the angled beams) that were cut from trees on our property. The stair treads are 4”x12” beams with a natural edge on two edges. These we had made at a local mill.

These (above) are going to be the treads. EVERYTHING had to be cleaned up, cut precisely and sanded. Most of the stringers had to be planed as well.

It started in the basement. First I had to build a platform for the first flight of stairs to come up to.

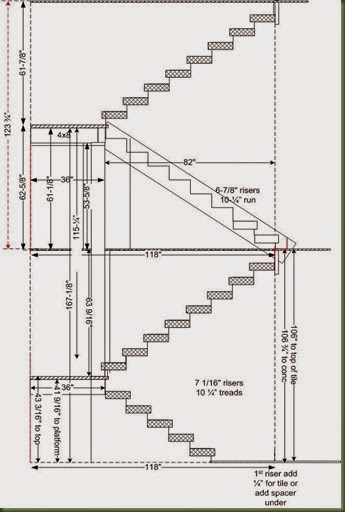

The trick to building stairs is to calculate the rise and run that you need to get to your top level, then divide by the number of stair treads you plan to have. In addition, according to code, the stair treads need to be at least 10” deep and no more than 7-3/4 high. That tread height also needs to be within 3/8” of each other tread. You also have to account for flooring thickness.

So I start by measuring .. twice … and snapping a line lengthwise down the length of the beam. Three of the stairway heights were about 63”, so that gave me (+/-) 7” x 9 rises and 10 1/4” x 8 runs. Using a carpenter’s square I measure out a 7” rise and 10 1/4” run, using that long line as a guide. You can sort of see my markings on the beam below. I have to measure the same on both sides. The inside of the beam has 1”x2” blocks tacked on to support each tread. The outside of the treads were marked so I could accurately drill pilot holes for the lag screws.

Speaking of lag screws, I used 1/2” x 8” screws and 2” bridge washers. What is a bridge washer, you ask? Here is a quiz. They are called bridge washers because:

A). they are primarily made and imported from Cuba as a “bridge” in import relations.

B) A man named Francoise de Pont invented them (pont=bridge)

C) They are used to bolt bridges together.

D) They look like buttons that held up old fashioned “britches”.

The answer? Who knows… i thought you knew!

Starting work on the 1st floor to second floor stairs

Once again, build the platform first. This is a rustic sawn log look made from 4”x8’ beams and 5” x5” posts.

We had to use a chain hoist several times to either move the finished stairs to a different spot, or to raise them to get so hidden bolts.

In this shot you can see the temporary 1”x2” blocks I used to hold the treads before they were bolted in.

Had to raise this set of stairs about 2’ to be able to get to they four lag screws hidden by a beam.

I used my hole hawg with a socket bit to drive the lag screws into the treads.

Pretty fancy rigging, eh?

Yay!~ no more ladders to get upstairs!!!!

finished!

Deb covered the treads with heavy construction paper to protect them during work. Tip thanks to Shelley Goodnight!

While all that was going on, Deb was busy busy busy pulling wire throughout the house.

So far she has used 2000’ of 12/2 wire, and we just bought another 1000’ roll. There are also hundred of receptacle boxes of various sizes.

So far she has used 2000’ of 12/2 wire, and we just bought another 1000’ roll. There are also hundred of receptacle boxes of various sizes.

Below, another thing we accomplished was completing the framing of the fireplace hearth/mantle areas. You can see two sets of posts protruding out that will hold some thick beams as mantles. We need to cover this whole thing with 1/2” concrete backer board before we can mortar river rock onto the face.

Next project will be plumbing unless the weather continues to warm, we will probably dig ditches for the water and electrical.

…but then again golf season is starting this week, and we’ve got that camping trip coming up in April …

Wow!!! Y'all are amazing. The stairs are amazing. Love the use of wood from your property.

ReplyDelete